Rapid National Upgrades and Rollouts: When to Outsource to a 3PL

By John Cox

National Accounts

Technical Transportation, Inc

Placing high volumes of new product, upgrading existing software, or modifying hardware components for clients can be an expensive undertaking for many manufacturers, especially if the client in question is a large brand with hundreds of locations spread across the country.

In the case of a multitude of installations at various locations, the customer will likely expect the manufacturer to cater to their requirements — which typically entails an aggressive rollout schedule with minimal impact to their day-to-day business.

Most manufacturers, however, don’t have the internal resources to dispatch their own team of field service personnel to handle such a time-compressed, nationwide endeavor without first adding headcount and training new FSEs across the country. New product placements, off-site upgrade requirements, or equipment swap outs complicate this scope even further when introducing specific requirements for equipment handling or where the work must be performed.

Even if a manufacturer did have the personnel at their disposal, nationwide, time-sensitive projects of this magnitude oftentimes tie-down those resources into full-time commitments that fall under non-revenue-generating activities. At the very least, these projects have the potential to take more time away from activities that contribute to organizational metrics – where the utilization of the manufacturer’s personnel actually adds value and profitability. The capacity impact that these projects have on a manufacturer could also compromise their current service levels and overall customer satisfaction within the day-to-day business of their broader client base.

When contemplating whether or not to engage an external partner to support these efforts versus looking to tackle them internally with existing resources, manufacturers should ask themselves:

- Do I have the right skillsets in-house to perform the job efficiently? As the manufacturer, your knowledge of the product and the customer will be unmatched. However, if you are placing a new product, or you must relocate the existing device, do you have the in-house capability to quickly, efficiently and carefully move the product off premises from your customer’s site and return and install it unharmed? Can you do it in a manner that minimizes downtime at each customer location (possibly after-hours)?

- Can I quickly source and scale talent and resources at a national level? Can you seamlessly and very quickly scale up your operations without incurring a significant capital investment in the form of more employees? Will your administrative and service personnel be willing and able to perform the work at odd hours? What do you do with the excess employee count once the project is completed?

- Can I provide local service to my customer? Local access to each of your customer sites is very important as it provides efficiency in two ways. First is the efficiency of lead time. When combined with a nearby technician (or partner team), a local presence that can serve as a forward stocking location, staging area, or service depot offers many advantages, including the ability to serve end-users quickly. Second, and more notable, is cost, because you don’t have to pay for items such as travel charges, and cross-country shipping charges, which can otherwise account for 20-50% of your total project costs.

- Can I manage all of the moving parts efficiently? Rapid, nationwide projects require multiple vendors to get the job done. Are you able to internally manage all the people, schedules, activities, communications and planning needed to be successful?

If you have questions about how to successfully implement time-sensitive product placements or roll out upgrades to devices in the field for your big-name clients, while keeping your other operations running smoothly and efficiently, then we invite you to click here and contact us today.

When Downtime Isn’t an Option for Spare Parts,Conventional Warehousing May Not be an Option Either

By Louis Black

Vice President, National Accounts

Technical Transportation, Inc

Complex equipment and technology usually serve an important purpose, and downtime of that equipment can be very costly, or even life-threatening, as it is in the medical field with MRI and C-ARM machines.

That high-pressure environment puts added responsibility on the manufacturers of these devices to keep replacement parts (and even replacement units) available for deployment at a moment’s notice to meet demand.

That dictates having a warehouse presence near any facilities that require same-day response. For many manufacturers, though, the traditional approach of owning and running the facilities needed for rapid nationwide reach can be very costly and adversely affect budgets.

The accessibility of on-demand warehousing today lightens this burden, but a successful replacement part program is not simply created through strategic warehousing and planning alone. It also needs the tactical support required to quickly deliver and install the replacement parts, and make sure the equipment is back up and running properly.

So where do you begin? When looking for a partner that can help you develop and run a critical parts replacement program, consider the following characteristics.

Traits of an Ideal Critical Parts Warehousing Partner

Flexible and Customizable—Your partner should be able to customize and scale a program to fully meet your needs — as well as your clients’. Whether it’s regional warehouse space with overnight delivery, or a location just down the street from a major client for urgent service, your partner should be able to procure the space and maintain the needed spare parts inventory.

Specialists in Your Industry—You don’t want a novice behind the wheels of your urgent maintenance calls. Make sure your partner is familiar with your industry and is willing to invest in compliance training of their team in order to quickly and efficiently replace parts and make repairs on your equipment.

Field Services Capabilities—Your partner’s field services reach should be as flexible and customizable as your warehousing solution. Whether you need them available 24/7 or just during the work week, they should have a nationwide reach and have an orientation towards customer service. After all, they are an extension of your brand to your customers.

A Single Source Provider—Finally, your partner should make things simple for you. There’s a lot of “moving parts” in any critical parts program, and your partner may have to use other subcontractors or vendors for additional support. However, you should never have to be directly involved in those processes. Your partner should be the single source you deal with for your parts program, and they should manage any additional partners or vendors separately (i.e. scheduling, invoicing, etc.).

Do you need help with your replacement parts logistics? TechTrans has a program specifically built for this need. Contact us today to learn more.

Tips for Express Carriers Forging into the White Glove Delivery Space

By Sean Horner

Vice President Operations

Technical Transportation, Inc

Last month, the TechTrans team attended the Express Carrier Association’s 2019 ECA Marketplace, where we had the opportunity to network with a number of express carriers and begin developing fruitful partnerships.

The conference has an interesting format that’s similar to speed-dating, where shippers like TechTrans sit at tables around a large convention room, and then each express carrier in attendance rotates around to each shipper in 15-minute increments. During each meeting, the companies discover whether or not they are a good fit for one another, and schedule follow-up discussions if a partnership seems beneficial.

Many express carriers have a unique background, as a large percentage used to be single-driver couriers, delivering small items (often letters, documents and other small packages) on cross-town routes. But as instant communications became more prevalent over the past 10-15 years, that work dwindled, and many couriers had to re-invent themselves to survive.

Today, these couriers-turned-express-carriers feature trucks with lift-gates vs smaller cars and vans, and they’ve learned the ins-and-outs of white glove delivery and residential delivery methods to help create a competitive advantage.

For current express carriers and those looking to enter the white glove logistics realm, we offer the following tips from a shipper’s perspective:

- Be willing to work — Demonstrating your eagerness and willingness to complete deliveries to the 100% satisfaction of all parties involved will go a long way in getting the attention of the top shippers

- Be willing to adapt — If you came from a courier background, then you likely know that you have to adapt to remain competitive. But in a world where the Amazon Effect is rapidly changing consumer perceptions and expectations, you will need to keep up the pace and be willing to adapt your company strategy, methods and procedures to stay ahead of the curve

- Become brand ambassadors — To keep your shipper, their clients and the end-customer happy, you have to be willing to upgrade your typical level of customer service and go the extra mile for everyone involved. You also have to be professional when you’re onsite and become a de facto extension of your shipper’s brand (and the brand of their customer(s) too)

- Stay on top of the latest technology — Technology changes at a rapid pace as well, and keeping abreast of the latest trends in logistics tech can create a competitive advantage for you. Especially technology that provides real-time information to all parties, including proof-of-delivery, shipment status and more. This can help you also compete better against larger companies.

If you’re an express carrier and would like some advice, or if you think TechTrans might be a good fit for you, then we invite you to contact us today.

Trimming Total Time to Install Creates Competitive Advantage for Life Science Equipment Manufacturers

By Phil Burnette

VP – National Account Sales

Technical Transportation, Inc

Though life science equipment manufacturers work hard to distinctly market their products’ selling points, when it comes down to it, there are typically only minor differences between competing products. Whether it’s a refrigerator, a freezer, a bio-safety cabinet, or a centrifuge, most units will have similar competitive performance capabilities and features as other brands.

So in today’s crowded market, where performance and product features may only slightly vary, what can you as a manufacturer do to boost your competitive advantage? Sure, you can lower the price or make some kind of incentive, but eventually, those roads cut into your profit margins.

The only real competitive advantage therefore, may come through reducing the total time to install — in other words, getting your products to your customers faster.

For the average piece of equipment sitting in a centralized warehouse, it has to get on a truck once ordered and then can take 8-10 days to arrive at its destination (often cross-country). But having your equipment in strategic regional warehousing hubs that are closer to your end-users can shorten that delivery window to 1-2 days, which suddenly become a distinct competitive advantage.

And while that sounds great in theory, actually buying or leasing multiple warehouses across the country can just as easily sink your profits, and isn’t the most effective solution either.

That is why you need a logistics partner that already has the required infrastructure in place. A partner who is flexible and can warehouse, store and ship your equipment from regional hubs allows you to put your equipment in the hands of customers quicker than the competition.

A regional hub program also helps you:

- Reduce Damages – By proactively moving your products to regional hubs and reducing the travel distance and time needed for each order, you also reduce the risk of damaging more delicate items such as cold storage equipment.

- Become Data-Driven – Use customer data to determine which product models should be stocked at your forward locations. Tailor your inventory to match what your historical customer needs, and incorporate sales forecasting to make sure you’ve got the right product at the right place for your customers.

- Quickly Replace Product – Products that are non-operational due to technical or operational issues or need a swap-out due to warranty issues or upgrades can mean significant unrealized profits for a manufacturer. Replacing units in the field can happen much quicker with the use of strategic regional hubs.

- Realize Revenue Faster – For many equipment deliveries, the product has to be delivered and functioning at the end user’s location before an invoice can be sent and subsequently paid. By trimming delivery times down to 1-2 days vs 8-10 days, you potentially get paid a week earlier than under a traditional model.

- Meet Modern Expectations – It’s no secret that Amazon is changing the game when it comes to the retail supply chain, and there’s no doubt that those expectations of instant gratification also trickle down to the medical and life sciences industry. A regional warehousing model helps assuage those expectations while building end-user satisfaction and loyalty.

There are logistics providers today who can provide these nationwide, flexible warehousing services. Services that can be customized to meet your needs and the needs of your end-users. Contact us today if you’d like to learn more.

The Impact of Electronic Logging Devices (ELD)

By Michael Pyle

Information Systems Manager

Technical Transportation, Inc

It’s been almost a year and a half since the U.S. Federal Motor Carrier Safety Administration’s (FMCSA) first electronic logging device (ELD) compliance deadline passed, and we’ve noted several trends that have resulted.

But first, let’s quickly review the rules. Since December 2017, commercial motor vehicles have been required to include ELDs to track drivers’ hours of service electronically versus paper logs.

At TechTrans, we’ve witnessed multiple benefits, and as with any new regulation or piece of technology, everyone has to make adjustments. Some top benefits and adjustments we’ve seen so far include:

- Teaching old dogs new tricks — It’s always difficult adjusting to new processes, and this mandate has been no different. With ELDs, drivers now have to plan their days and their routes better to maximize efficiently, because the technology leaves no room for “fudging”. And that’s typically better for everyone. But the reality is that many drivers now drive fewer miles per day, which can also mean less pay, which doesn’t help with the industry’s current driver shortage.

- Safety — A main focus of the regulations, as well as its top benefit, is better overall road safety. ELDs help keep drivers, carriers and logistics companies honest when it comes to how much time a driver spends on the road. The typical rule is that a driver can only drive 11 hours in a 14-hour time period, after which they must rest for 10 consecutive hours before hitting the road again. ELDs help confirm this mandate is met, ensuring higher safety for everyone.

- Efficiency & Accuracy — Keeping paper driving logs could be a hassle, mainly because of the keyword “paper.” With ELDs, this system is completely digitized, meaning it’s less prone to human error and it makes reporting more efficient. And should law enforcement request a driver’s log, they can quickly pull it up on their required automatic onboard recording device (AOBRD) and provide a clear picture of the given situation. This means the driver could be back on the road faster.

- Saves Drivers Money — According to ELDFacts.com, the added efficiencies of a paperless system also enables more billable driving time, decreased fuel costs and reduced man-hours needed to complete and submit paperwork.

The website gives the following example of cost-savings:

“Consider an owner/operator running a flatbed operation at $2.47/mile, averaging 50 MPH, and running approximately 1900 miles a week. That driver would realize:

- 1.5 hours/week from reduced paperwork = $185.25/week in potential new driving (billable) time

- 1.5 hours/week of rounding to the nearest minute = $185.25/week in potential new driving (billable) time

- Commanding a higher rate based on proven HOS compliance ($2.60 compared to $2.47) = $247/week

- Potential reduction of one OOS violation a year, resulting in one more day on the road = $20.58/week

- Saving on potential fines from form and manner violations = $6.25/week”

Though there is always an adjustment period when enacting new processes and technologies across an industry, we see several resulting changes from the ELD mandates that are bringing about positive outcomes for drivers and the companies that hire them.For more information about the ELD mandates and their impacts on the industry, feel free to contact us today.

What Goes Into Pricing a Shipment?

Image credit to Transport Executive

By John Cox

National Accounts

Technical Transportation, Inc

For many manufacturers and shippers, the expense of shipping large, complex technology and equipment can seem like a daunting task.

There are multiple factors and variables involved, and while it may be confusing comparing quotes to get the best available value for each delivery, there are ways to make your pricing more consistent and predictable.

Accurately Understand What’s Involved

The first step is specifically outlining what’s involved in the process before it can be accurately priced out. It’s critical for you and your logistics partner to understand and communicate your transportation requirements in terms of days/hours of service, lead times expected, type of equipment, special delivery/install requirements, delivery facility conditions and accessibility, and factors know or unknown for consideration.

If the expected deliverables and compliances are not carefully vetted on the front end, you will predictably end up with additional accessorial costs on the backend. Example: your logistics provider claims, “I didn’t know we had to do this. It wasn’t communicated in the delivery instructions”. More often than not, as a manufacturer or shipper you’ll end up approving added costs to fix or mask problems to avoid a poor customer experience that could have been avoided if defined properly from the beginning.

It’s also important for you to consider current issues and trends in the transportation industry. One prime example is the ongoing driver shortage. Every logistics provider has a “we’re hiring” sign up right now, and transporting goods comes at a premium.

Add to the fact that many deliveries of high-valued, sensitive equipment such as medical imaging instruments and the like require coordinated, scheduled appointments versus “we’ll deliver it sometime before 8 p.m.”, and this means prices can potentially be affected even further.

Efficiencies in Single-Source Provider

Manufacturers should also consider single-source logistics providers, or those that can manage the entire supply chain for you – from initial site assessment and product pickup, to final mile delivery, install and making the equipment operational. Doing so can make your transportation and delivery costs more predictable.

Such a scenario eliminates the need to hire the 4-5 vendors required to get your product from point A to point B.

The ideal single-source partner would first assess your needs for transportation, for delivery to your end-customer, and for any on-site activities such as pre-delivery site surveys to final unpacking and setup, making sure the program can be delivered successfully and meets everyone’s expectations.

That partner would package those services into a repeatable, hassle-free process that can range from shipment activity of “normal business operations,” all the way through to an entirely customized logistics solution based on your unique requirements. From there, you as the customer would only have to manage exceptions and leave the rest up to your partner.

Appropriate Skill Sets for Delivery Team

It’s also important to evaluate the skill sets of your logistics partner’s logistics teams. Do they intimately know and understand your product? Can they deliver and install it in an efficient and expert manner at a high rate of success?

You also want a provider that specializes in your industry. Unless they have experience with products or equipment similar to what you need to transport, it is unlikely they will have the processes and knowledge base already in place to successfully deliver your products. This can ultimately mean greater costs for you, if they are having to learn by trial and error about your product, processes, and expected deliverables, and how to effectively perform to your and your customers’ expectations.

Opportunity Cost of Not Getting it Right

Finally, you need to consider the potential cost of not getting it right the first time. Sure, a smorgasbord of in-house personnel and a multitude of vendors might be a little cheaper than a specialized provider, but if you don’t have the proper skill effectively defined, and you roll the dice, what will it cost your organization for a high-profile failure?

Ultimately, most manufacturers or shippers don’t factor in the cost it takes to manage all those internal and external resources that come at a “cheaper price.” When you look at the value of your time in having to manage so many moving parts, you ultimately are spending more resources and effort on coordination when you could be spending it in value-added functions.

So make sure you do your homework, and if you need any help understanding the logistics landscape, we’re happy to help answer any questions with no strings attached. Feel free to reach out to us today!

Customer Service is More Than a Luxury with High-End Residential Logistics

By Louis Black

VP, National Account Sales

Technical Transportation, Inc

According to research, the global luxury furniture market is expected to reach $29 million by 2022, growing at a rate of 4% since 2014. The biggest reason for the growth in this sector is the rise in disposable income that leads to a rise in demand for luxury living. As the market for high-end home appliances and furniture grows, the need for quality logistics providers to perform premium in-home delivery and installation services also increases.

It stands to reason that when people buy premium, expensive items, your average delivery company with two guys in dirty t-shirts and torn blue jeans won’t cut it. With luxury purchases, the customer’s expectations are extremely high, and the level of service must meet or exceed those expectations — for the end customer as well as the manufacturer or retailer.

For example, if a person buys a $14,000 massage chair from a luxury retailer, they expect to receive a premium experience when it is delivered in their home, akin to the price they paid. That means for retailers or manufacturers of such products, excellent service needs to accompany the product all the way to its final destination.

The good news is, there are logistics companies that can cater to those needs. When looking for a partner that can ensure a premium experience for your customers, consider the following:

- Are they flexible? – Is your provider willing and able to change their delivery operations in mid-stream to meet unexpected and unknown needs or requirements? Customers will expect anyone who handles their product to go the extra mile – so make sure your logistics provider can deliver.

- Do they provide great customer service? – This translates to going beyond just getting product safely through the front door. That might mean helping the customer move furniture in the home to accommodate the new piece, or helping with setup to get the item operational or even fully built. If your logistics provider can’t deliver concierge-level, problem-solving service with the utmost professionalism, then they won’t be the right provider for this type of delivery.

- Will they be your brand ambassadors? – To take customer service a step further, your logistics partner should be willing to learn and understand your expectations or even the nuances of the products they are delivering. That way they become a seamless part of your organization, your culture and your mission.

- Do they specialize in white glove delivery? – Beyond handling product with care, 3PLs in the luxury residential space must understand the equipment, furniture or appliances they are delivering and installing are highly expensive — potentially one-of-a-kind products — which must be flawlessly delivered into the customer’s home environment. This also must be done without disturbing and damaging anything else in the home, or leaving any mess or debris.

- Do they have the right experience? – Make sure your logistics partner has the proven expertise with similar delicate, heavy-weight or expensive products. A standard white-appliance delivery provider will typically not have the background necessary to perform premium services for products carrying a premium price tag.

More importantly, having one vendor and point of contact that handles everything from initial pick-up to final install and setup means you have less processes/people to manage. It also gives you the assurance that your service expectations won’t get watered down through a lengthy supply chain.

In the luxury residential logistics space, your white glove delivery and install team are the final leg of the sales process and must represent your own brand, truly acting as an extension of your company while in the customer’s home. That way, you can feel confident that your end customers will receive the best customer experience from the moment they enter your store or visit your website, all the way to when they are enjoying your product in their home.

If you have questions on our residential services, feel free to contact us and one of our experts will help provide the answer.

Reducing the Carbon Footprint Still a Work-in-Progress for the Complex Equipment Logistics Space

By Len Batcha

President

Technical Transportation, Inc

Going green is big business. As consumers change their personal habits — carrying reusable aluminum straws and canvas grocery bags, trading in their old cars for Prius or Tesla and buying local and certified organic whenever possible — they also are looking to companies to take on dynamic industry changes as well.

Retailers like Amazon, Walmart and Best Buy have made innovations in getting small packages delivered to businesses and residences faster than ever, but incorporating more eco-conscious practices has proven challenging.

For these companies, the use of electronic devices to deliver small packages has been a major topic, though with only mixed success. This is in part because electric power isn’t necessarily as “clean” as it seems at first glance.

Take electric-powered vehicles, for instance. Although they do put out fewer emissions than gas or even hybrid vehicles, these aren’t necessarily the answer. It takes electricity to use electricity, which currently creates an even bigger carbon footprint.

Drones are another solution drawing much interest. However, they’re problematic in residential areas because of the potential of highly trafficked air spaces. They might have applications in more rural areas, but extending the life of the batteries for this to work might not result in energy-use or carbon footprint reductions.

eBicycles have been workable in urban areas, though geography plays a role in their efficiency. In places like San Francisco and Seattle, steep hills mean bikes require extra charging to generate more electrical power.

The space of highly complex and sensitive equipment, however, has proven even more challenging with regards to emissions reduction. The specialized nature of this kind of cargo — in terms of not only complexity but also sheer scale — demands individual assessment and personalized service.

For this reason, Artificial Intelligence (AI) — which is becoming a major player in other industries — isn’t taking the same hold here. For such a model to be successful, the AI would have to be programmed to analyze facilities and make decisions on how to best optimize the equipment at hand. This would require constant assessment and calculation. Any time you introduce any kind of anomaly into the mix — a frequent occurrence in this complex equipment space — human interaction and decision making is necessary to ensure success.

That isn’t to say we will escape the AI component in its entirety. AI could be used to take on more of the proof-of-performance functions such as taking pictures to show completion and accuracy of the delivery.

The actual transport segment does offer some possibilities as well. Self-driving and autonomous vehicles may be used in cases where multiple deliveries to multiple areas can maximize efficiency and energy usage. In the complex equipment space specifically, box trucks running on diesel will eventually be replaced by low-fuel trucks as they become more affordable. We’re already seeing this application in medium and light-weight trucks, which can operate at fewer kilowatts per hour.

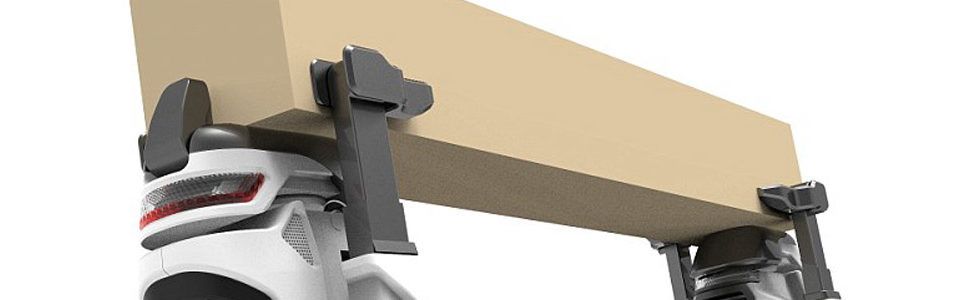

Beyond transport, the use of robotics to actually deliver and install complex equipment may only solve part of the problem. Though a robot may be sturdy enough to handle heavy-weight equipment, it would also have to be able to maneuver with the necessary agility to get the equipment into often tight or limited-area floor spaces. Right now, this component of the supply chain is better handled with a trained crew that can better assess the situation on the spot and make informed decisions that best serve the equipment and end-user’s needs.

Though measures to improve the carbon footprint are advancing every day, in the logistics segment of highly complex, high-value, heavy weight or complex equipment, this is still a distant reality.

Contact us today and we can provide counsel and support to help you make informed decisions.

Finding the Prescription for Pharmacy Automation Logistics

By Phil Burnette

Vice President, National Account Sales

Technical Transportation, Inc

The world of pharmacy automation is still in its infancy, but the industry is quickly growing. And this growth brings along many logistical challenges for manufacturers that need to ship, deliver and install this sensitive automated equipment to pharmacies across the country.

While pharmacy automation equipment ranges in size, the more prevalent solutions feature large, complex robotic units that mechanically dispense pharmaceuticals. The technology is now being implemented down to the retail level, which will bring more efficiency and accuracy to traditional operations. It also presents the challenge of safely putting this technology into a wide variety of retail footprints with minimal operational downtime or disruption to the facility.

There are still a number of obstacles to overcome, especially compounded by the fact that space in these central fulfillment and retail facilities is at a premium. Yet the right prescription for manufacturers of pharmaceutical automation equipment may be as simple as selecting the right logistics partner to help them bring their products to market. Listed below are items that need to be considered:

- Skilled team – With the growth of this industry, logistics and service providers will play an even bigger, value-added role in getting pharmacy automation technology to market, and making it operational as expediently as possible. The right logistics provider for the job should possess the infrastructure and expertise to transition the equipment from the distribution facility to operational with no damage to product, property, or personnel.

- Certified provider – The pharmaceutical industry is highly regulated, so it’s critical to have a partner that understands the processes and requirements of the industry and can navigate you through any challenges. They should also be intimately knowledgeable about your products and execute compliance to processes and procedures for delivery and installation.

- More than just delivery – These complex machines require logistics and service partners that are willing and able to go above and beyond simple product delivery. The best partners will unpack, expertly assemble and set up the unit so it is operational for the end-user in the shortest amount of time possible. They should also be able to do pre-install site surveys and assessments to ensure there will be no obstacles for a seamless installation, as well as a post-site review to make sure all packaging materials are removed from the site prior to departure.

- Training for end-users – The right partner should also be able to train end users on how to operate the technology and troubleshoot any problems that may arise. This should be completed the day-of or day-after the product is installed, so the end customer can begin use of the system as quickly as possible.

- Single source partner – Your logistics and service partner should be an extension of your team, therefore, having a single-source provider takes away the complications of scheduling and coordinating field service and technician teams that are required for each implementation. The right provider should offer a single point of contact for all activities, questions and concerns, as well as, a single consolidated invoice for simplified payment. And ultimately, the peace of mind that your supply chain is being managed by experts in your growing field of pharmacy automation.

Are you ready for the changes impacting the pharmacy industry? Contact us today and we can provide counsel and support to help you make informed decisions.

TechPlus: A Service Above and Beyond Delivery Expectations

By Sean Horner

Vice President Operations

Technical Transportation, Inc

A major difference between a logistics provider and a logistics partner is the partner’s willingness and ability to go the extra mile and solve a multitude of issues or problems that may arise in your supply chain operations.

Beyond getting a manufacturer’s product from point A to point B, and even performing basic debris removal and setting product in place, some customers need more specialized services. That’s where our TechPlus services come in, offering a range of additional services that go above and beyond, including:

- Product Assembly

- Programming / Configurations

- Diagnostic Testing

- Software Upgrades

- Installation / Networking

With these options available under our service umbrella, our customers with heavy weight or highly specialized equipment don’t have to source these separately, nor do they have to send their own field service personnel, thus incurring additional expenses (sometime to the tune of $200-$400 per hour).

With our TechPlus services, we employ delivery crews that do the basics, and then we coordinate our more technical teams to arrive as the shipment arrives, so the setup services are done on the spot, reducing product downtime by making it operational as quickly as possible. We also coordinate scheduling with the manufacturer’s internal people as well, to minimize any of their time or dollars spent to manage the process.

In our TechPlus portal, we also set up electronic checklists for our clients to aid in transparency and ensure the required steps are completed. This includes conducting site surveys ahead of the shipment’s arrival to determine if there are any issues on site that should be anticipated during delivery, assembly and set up. The portal also features:

- Seamless status updates

- Photos of the installed product(s)

- Necessary signed documentation

- And more.

Our TechPlus services are efficiently designed to get our clients’ products operational as soon as possible, saving everyone both time and money. Contact us today to learn more.