Reducing the Carbon Footprint Still a Work-in-Progress for the Complex Equipment Logistics Space

By Len Batcha

President

Technical Transportation, Inc

Going green is big business. As consumers change their personal habits — carrying reusable aluminum straws and canvas grocery bags, trading in their old cars for Prius or Tesla and buying local and certified organic whenever possible — they also are looking to companies to take on dynamic industry changes as well.

Retailers like Amazon, Walmart and Best Buy have made innovations in getting small packages delivered to businesses and residences faster than ever, but incorporating more eco-conscious practices has proven challenging.

For these companies, the use of electronic devices to deliver small packages has been a major topic, though with only mixed success. This is in part because electric power isn’t necessarily as “clean” as it seems at first glance.

Take electric-powered vehicles, for instance. Although they do put out fewer emissions than gas or even hybrid vehicles, these aren’t necessarily the answer. It takes electricity to use electricity, which currently creates an even bigger carbon footprint.

Drones are another solution drawing much interest. However, they’re problematic in residential areas because of the potential of highly trafficked air spaces. They might have applications in more rural areas, but extending the life of the batteries for this to work might not result in energy-use or carbon footprint reductions.

eBicycles have been workable in urban areas, though geography plays a role in their efficiency. In places like San Francisco and Seattle, steep hills mean bikes require extra charging to generate more electrical power.

The space of highly complex and sensitive equipment, however, has proven even more challenging with regards to emissions reduction. The specialized nature of this kind of cargo — in terms of not only complexity but also sheer scale — demands individual assessment and personalized service.

For this reason, Artificial Intelligence (AI) — which is becoming a major player in other industries — isn’t taking the same hold here. For such a model to be successful, the AI would have to be programmed to analyze facilities and make decisions on how to best optimize the equipment at hand. This would require constant assessment and calculation. Any time you introduce any kind of anomaly into the mix — a frequent occurrence in this complex equipment space — human interaction and decision making is necessary to ensure success.

That isn’t to say we will escape the AI component in its entirety. AI could be used to take on more of the proof-of-performance functions such as taking pictures to show completion and accuracy of the delivery.

The actual transport segment does offer some possibilities as well. Self-driving and autonomous vehicles may be used in cases where multiple deliveries to multiple areas can maximize efficiency and energy usage. In the complex equipment space specifically, box trucks running on diesel will eventually be replaced by low-fuel trucks as they become more affordable. We’re already seeing this application in medium and light-weight trucks, which can operate at fewer kilowatts per hour.

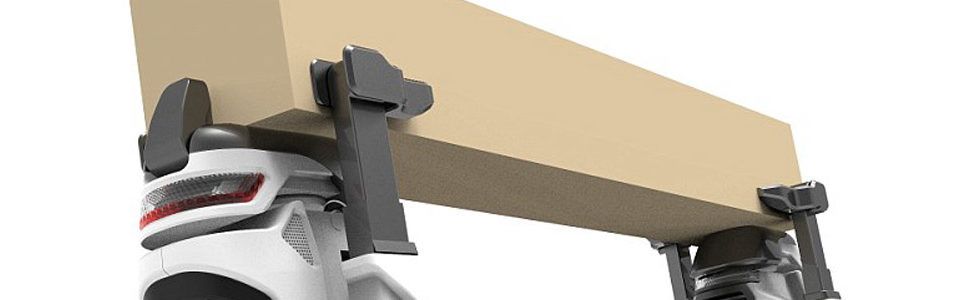

Beyond transport, the use of robotics to actually deliver and install complex equipment may only solve part of the problem. Though a robot may be sturdy enough to handle heavy-weight equipment, it would also have to be able to maneuver with the necessary agility to get the equipment into often tight or limited-area floor spaces. Right now, this component of the supply chain is better handled with a trained crew that can better assess the situation on the spot and make informed decisions that best serve the equipment and end-user’s needs.

Though measures to improve the carbon footprint are advancing every day, in the logistics segment of highly complex, high-value, heavy weight or complex equipment, this is still a distant reality.

Contact us today and we can provide counsel and support to help you make informed decisions.